VT-447(B)

Prepreg/Laminate

UL Approval: E214381 Version: 12/12/2024

/127/128/130

Storage Condition & Shelf Life

|

|

Prepreg |

Laminate |

|

Storage Condition |

Temperature |

< 23℃ (73℉) |

< 5℃ (41℉) |

Room |

|

Relative Humidity |

< 55% RH |

/ |

/ |

|

Shelf Life |

3 Months |

6 Months |

24 Months (airproof) |

Precautions In Handling

- The prepreg exceeding shelf time should be retested.

- Take care in handling thin core laminates as they are easily damaged.

- If the prepreg is not consumed within 48hrs after opening the vacuum package, it is recommended that the bags be resealed.

- Material is available in both long and short grain. The grain direction is indicated on the label with an arrow.

Prepreg Availability

|

PP Type |

Resin Content |

Press Thickness (mil) |

Dk |

|

Df |

|

@ 1GHz |

@ 5GHz |

@ 1GHz |

@ 5GHz |

|

7628 |

45% |

7.6 |

4.34 |

4.24 |

0.012 |

0.013 |

|

2116 |

54% |

4.8 |

4.07 |

3.97 |

0.014 |

0.015 |

|

1080 |

64% |

3.5 |

3.90 |

3.76 |

0.015 |

0.016 |

① Press thickness test condition---Prepreg lamination size 18”*24”, Copper Foil---1oz/1oz, Flow---about 5%;

② Make laminated prepreg to micro-section and measure the thickness with microscope; this thickness is used for resistance design calculation.

③ The thickness measured with micrometer is 0.2~0.4 mil larger than that measured with micro-section; and mainly used for total thickness design calculation.

Laminate Availablity

VT-447(B) Laminates are available in thickness from .003” up to .094” and with the copper foil from 1/4oz to 12oz;

Ventec can supply either reverse treated (RT) or double side treated copper foil.

DK values are for impedance design.

|

Core Thickness (Inches) |

Stack-up |

Resin Content |

Dk |

Df |

|

@ 1GHz |

@ 5GHz |

@ 1GHz |

@ 5GHz |

|

0.003 |

1-1080 |

64% |

3.85 |

3.76 |

0.015 |

0.016 |

|

0.005 |

1-2116 |

54% |

4.07 |

3.97 |

0.014 |

0.015 |

|

0.006 |

2-1080 |

64% |

3.85 |

3.76 |

0.015 |

0.016 |

|

0.008 |

1-7628 |

45% |

4.34 |

4.24 |

0.012 |

0.013 |

|

0.010 |

2-2116 |

54% |

4.07 |

3.97 |

0.014 |

0.015 |

|

0.014 |

2-7628 |

41% |

4.44 |

4.34 |

0.012 |

0.013 |

|

0.016 |

2-7628 |

45% |

4.31 |

4.21 |

0.013 |

0.014 |

|

0.021 |

3-7628 |

41% |

4.44 |

4.34 |

0.012 |

0.013 |

|

0.028 |

4-7628 |

41% |

4.44 |

4.34 |

0.012 |

0.013 |

|

0.031 |

4-7628 |

45% |

4.34 |

4.24 |

0.012 |

0.013 |

|

0.039 |

5-7628 |

45% |

4.34 |

4.24 |

0.012 |

0.013 |

|

0.042 |

6-7628 |

41% |

4.44 |

4.34 |

0.012 |

0.013 |

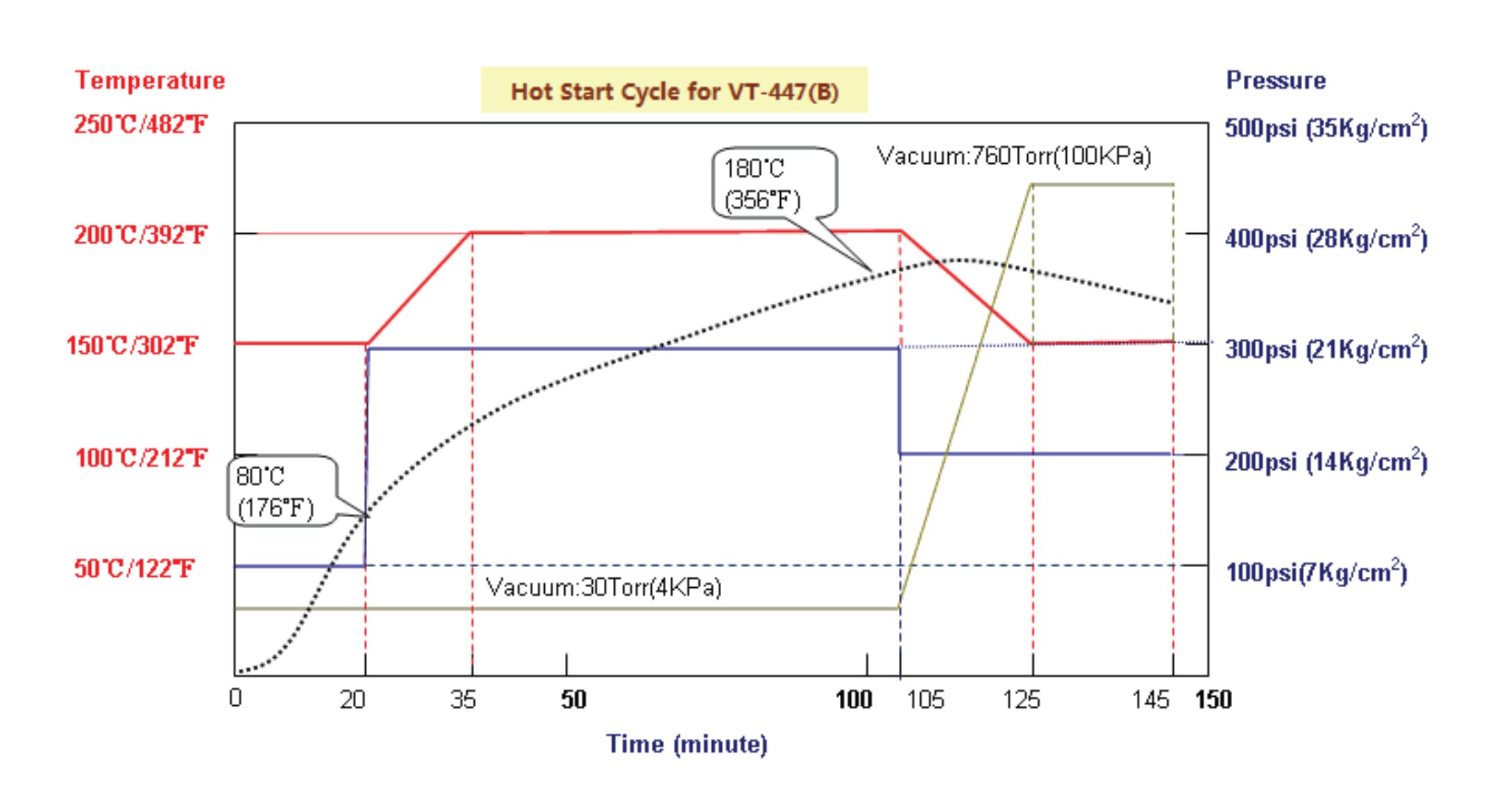

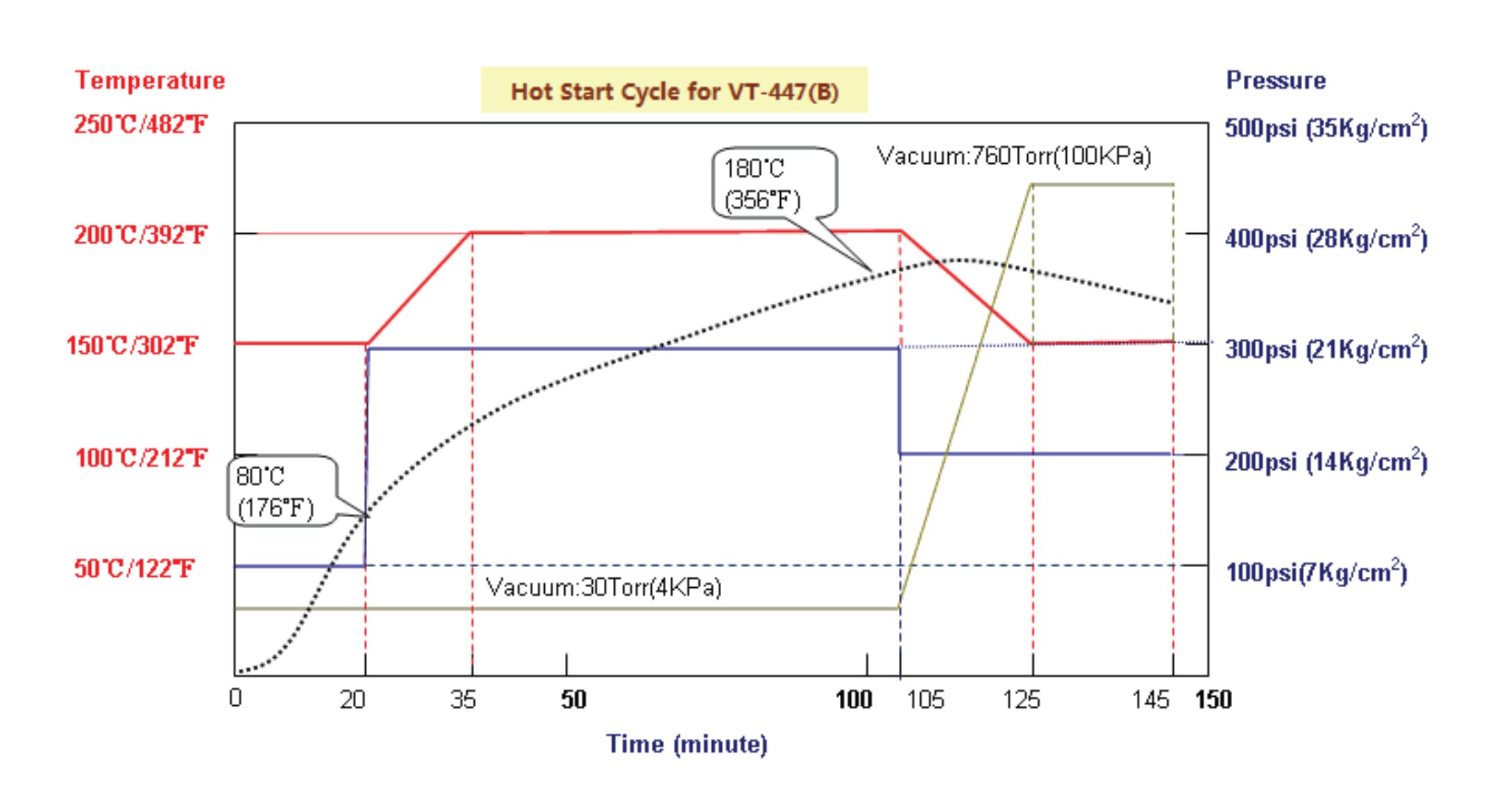

Press Condition

1. Heating rate (Rate of Rise) of material [Material Temperature]: Programmable Press: 1.5-3.0ºC/min (3~5ºF/min). Manual Press:3~6ºC /min (5~10ºF/min)

2. Curing Temperature & Time: >60min at more than 185ºC and peak temperature>195ºC

3. Full Pressure: ≥300psi

4. Vacuuming should be continued until over 140ºC [Material Temperature]

5. Cold Press condition: Keep Plate @ Room Temperature by water; Pressure:100psi; Keep Time:60minutes

Typical Drilling Parameters

|

1. Spindle Speed: |

120-180 |

KRPM |

|

2. Feed Rate: |

120-220 |

Inch / min |

|

3. Retract Rate: |

596-1000 |

Inch / min |

|

4. Chip Load: |

0.6-2.0 |

Mil / Rev |

|

5. Entry Board: |

t0.15mm AI |

- |

|

6. Stack Amount (t1.6mm): |

1-3 stacks |

- |

Desmearing Process

Packaging and baking recommendation

- It is recommended to bake the board before packaging at 125ºC/4~8h to avoid moisture causing a decrease in heat resistance.

- If the PCBs needs to be stored for a long time before use, it is recommended to use aluminum foil vacuum packaging.

- If exceed 3 months after packaging , It is best to bake the PCBs at 125ºC/4~6h before assembly before use.