VT-441C

Laminate/Prepreg

UL Approval: E214381 Version: 05/08/2025

/127/128

Storage Condition & Shelf Life

|

|

Prepreg |

Laminate |

|

Storage Condition |

Temperature |

< 23℃ (73℉) |

< 5℃ (41℉) |

Room |

|

Relative Humidity |

< 55% RH |

/ |

/ |

|

Shelf Life |

3 Months |

6 Months |

24 Months |

- The prepreg exceeding shelf time should be retested.

- Take care in handling thin core laminates as they are easily damaged.

- If the prepreg is not consumed within 48hrs after opening the vacuum package, it is recommended that the bags be resealed.

- Material is available in both long and short grain. The grain direction is indicated on the label with an arrow.

Precautions In Handling

- Please be careful when single ply of 1080 prepreg is designed to the dielectric layer.

- VT-441C has weaker thermal resistance than regular VT-441. Please be very careful when 8L and higher layer count is designed or dielectric with single ply of 1080.

- VT-441C Dk is a little higher than VT-441. Please take it into consideration whenever impendence control is required.

- CTI 600 only can be guaranteed when the full stack-up is from VT-441C material.

- Please be noticed that the surface roughness and clearness affect CTI rating.

Prepreg Availability

|

PP Type |

Resin Content |

Press Thickness (mil) |

DK |

DF |

|

@ 1GHz |

@ 2GHz |

@ 5GHz |

@ 10GHz |

@ 1GHz |

@ 2GHz |

@ 5GHz |

@ 10GHz |

|

7628 |

50% |

8.0 |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

7628 |

46% |

7.5 |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

1506 |

54% |

7.0 |

4.5 |

4.5 |

4.4 |

4.4 |

0.012 |

0.012 |

0.013 |

0.013 |

|

2116 |

58% |

5.0 |

4.5 |

4.5 |

4.4 |

4.4 |

0.012 |

0.012 |

0.013 |

0.013 |

|

1080 |

68% |

3.1 |

4.3 |

4.3 |

4.2 |

4.2 |

0.012 |

0.012 |

0.013 |

0.013 |

|

106 |

76% |

2.3 |

4.1 |

4.1 |

4.0 |

4.0 |

0.013 |

0.013 |

0.014 |

0.014 |

Remark:

More types could be available upon request.

When 2116PP or/and 1080PP is used as the outmost layer, 2-ply minimum is required to ensure CTI 600.

2-Ply 106 prepreg can only withstand CTI 400V.

Laminate Availablity

|

Core Thickness |

Stack-up |

Resin Content |

DK |

DF |

|

inches |

@ 1GHz |

@ 2GHz |

@ 5GHz |

@ 10GHz |

@ 1GHz |

@ 2GHz |

@ 5GHz |

@ 10GHz |

|

0.008 |

1-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.012 |

2-1506 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.015 |

2-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.016 |

2-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.018 |

2-7628 + 1-1080 |

48% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.020 |

2-7628 + 1-2116 |

47% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.024 |

3-7625 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.028 |

4-7628 |

42% |

4.7 |

4.7 |

4.6 |

4.6 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.030 |

4-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.036 |

5-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.042 |

6-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.054 |

7-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.057 |

8-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.058 |

8-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.060 |

8-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

Dk values are for impedance design

More types could be available upon request.

In order to satisfy CTI ≥600V, please don’t design 0.10mm in outer layer.

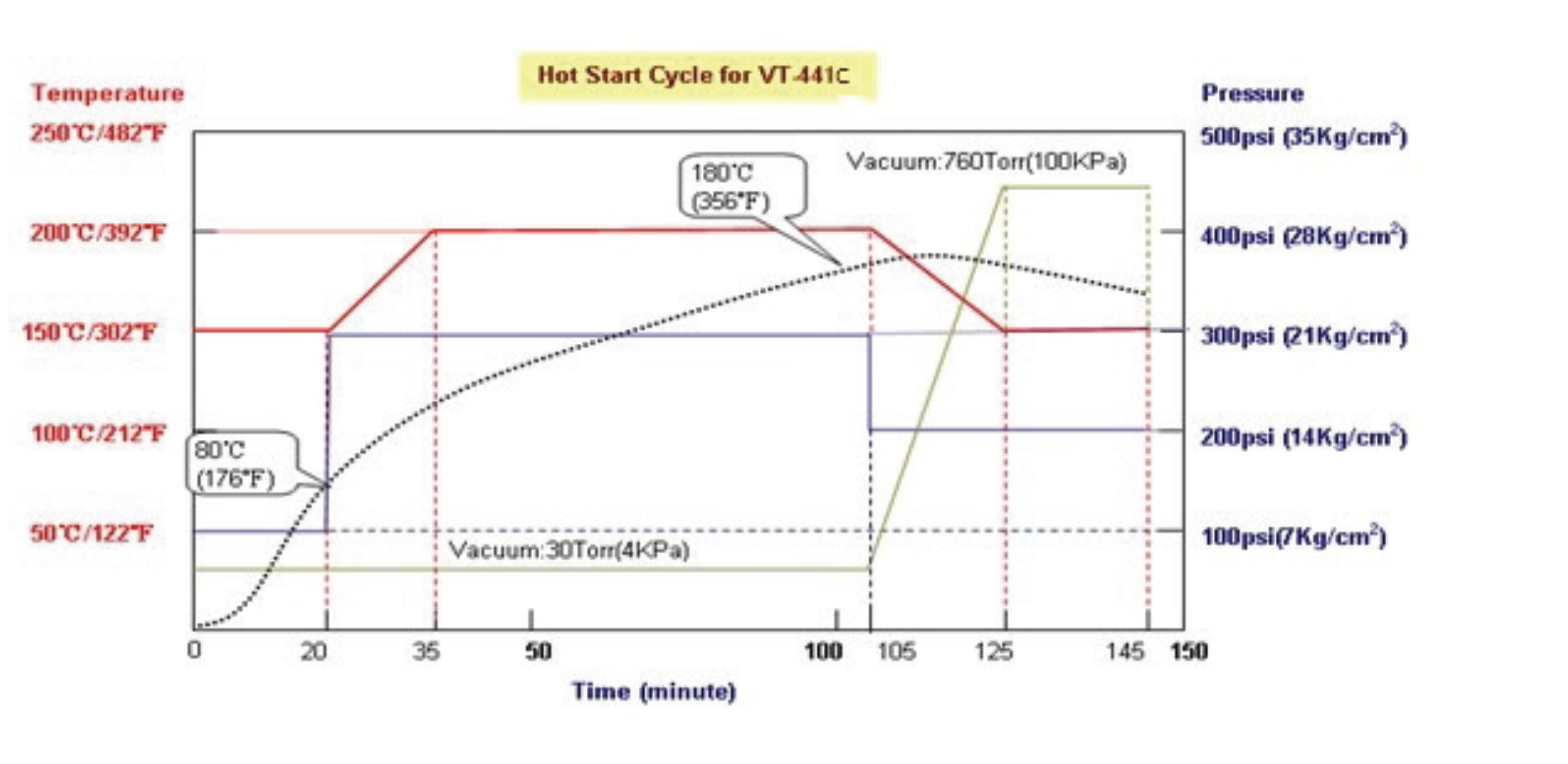

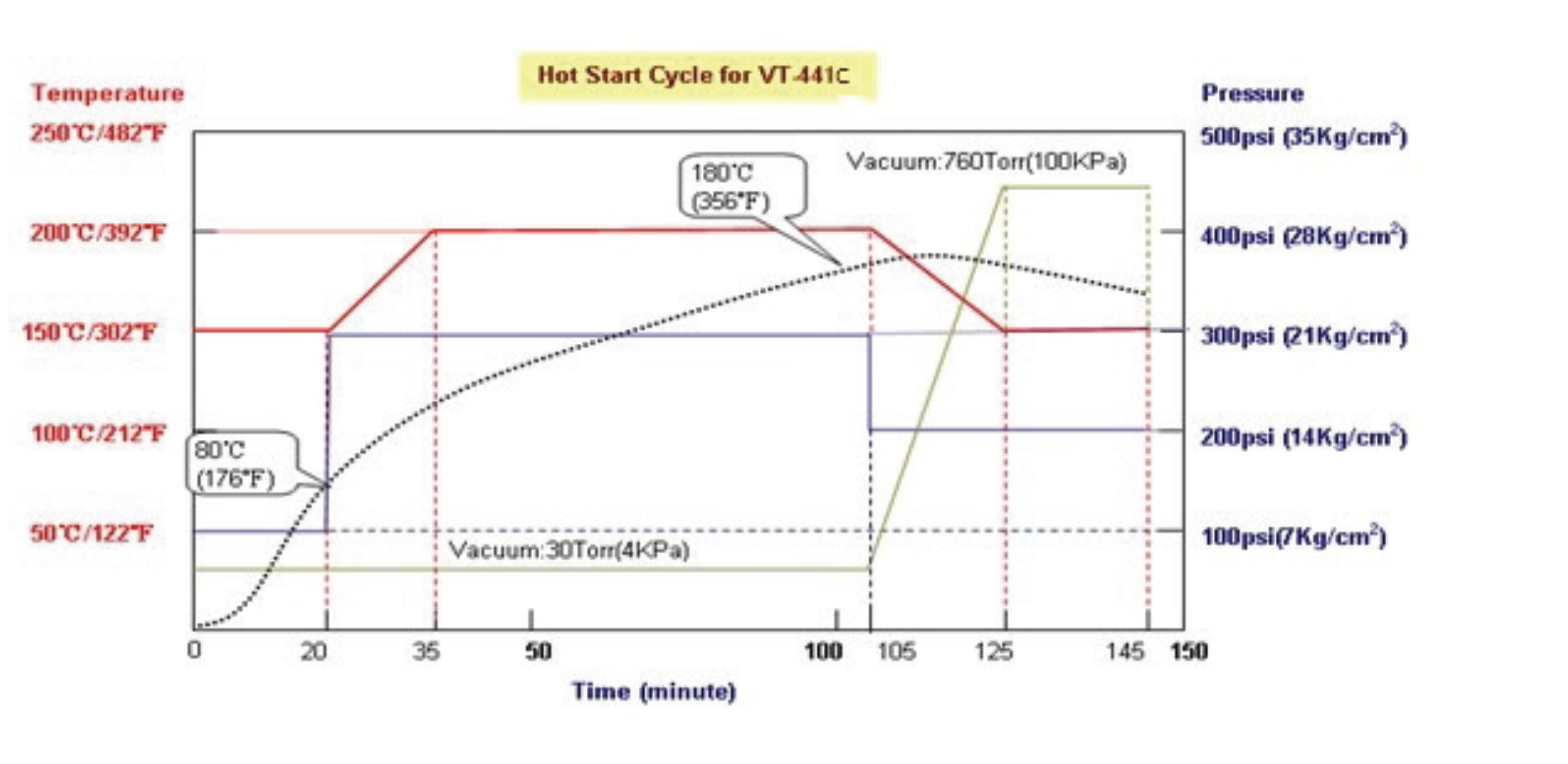

Press Condition

1. Heating rate (Rate of Rise) of material [Material Temperature]: Programmable Press: ≥2.0ºC/min

2. Curing Temperature & Time: >60min at more than 180ºC (356ºF) Material temperature

3. Full Pressure: ≥300psi and temperature to apply full pressure before ≤80ºC

4. Vacuuming should be continued until over 140ºC (284ºF) [Material Temperature]

5. Cold Press condition: Keep Plate @ Room Temperature by water; Pressure:100psi; Keep Time: 60minutes

Typical Drilling Conditions

|

Diameter |

Stack Height |

Spindle (KRPM) |

Infeed (mm/s) |

Retract (mm/s) |

Hit Count |

|

0.25mm |

1 PNL/Stack |

130 |

38 |

300 |

800 |

|

0.30mm |

1 PNL/Stack |

130 |

38 |

300 |

800 |

|

0.60mm |

1 PNL/Stack |

80 |

43 |

300 |

800 |

1. Excessive wear of carbide drill bits. Diamond coated drill bits preferred;

2. LE Aluminum sheet and white phenolic entry board are preferred;

Desmearing Process

The de-smearing rate of VT-441C is less than regular VT-441. 1 time vertical de-smearing is preferred.

Please examine hole wall to check de-smearing effect.

Typical de-smearing rate for reference only:

|

1x De-smearing |

Supplier |

Chemical |

|

0.27mg/cm2 |

Atotech |

Alkaline Permanganate |

Packaging and baking recommendation

1. It is recommended to bake the board before packaging at 125ºC/4~8h to avoid moisture causing a decrease in heat resistance.

2. If the PCBs needs to be stored for a long time before use, it is recommended to use aluminum foil vacuum packaging.

3. If exceed 3 months after packaging , It is best to bake the PCBs at 125ºC/4~6h before assembly before use.